- All

- Cables

- Delivery

- Electronics

- Gear Units

- Geared Motors

- Hygienic Washdown

- Motion Control

- Motor

- Power Tips

- Power Transmission

- Quality

- Rack and Pinion

- Service

- ServoStop Brake System

- STOBER

- System

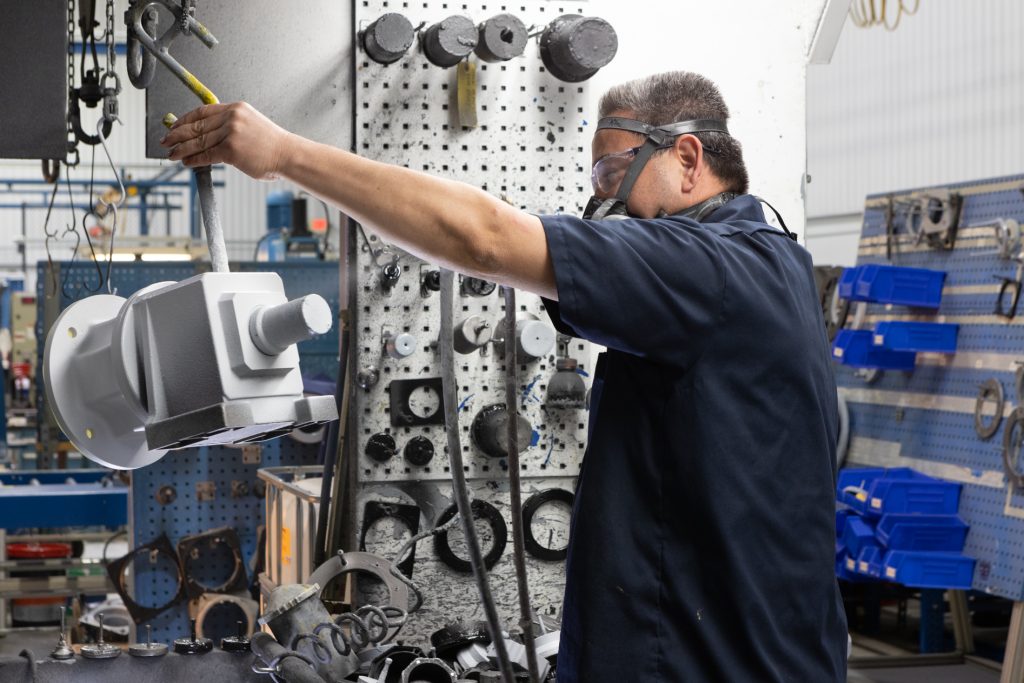

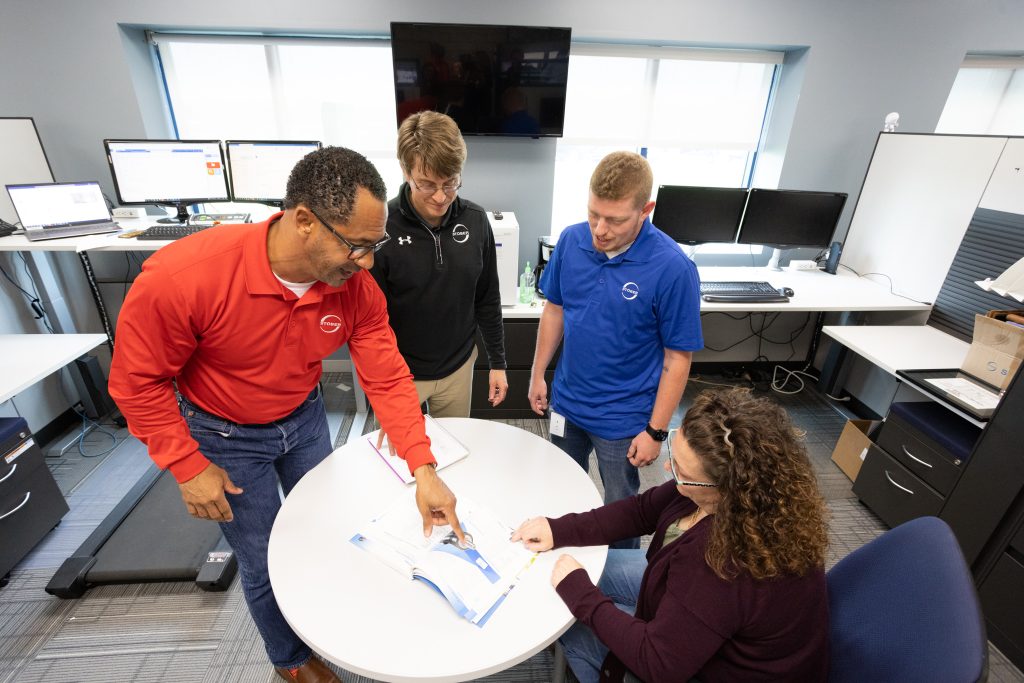

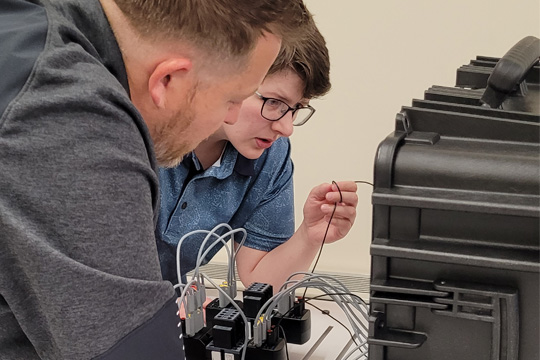

Gearing up for success: Installation training at food processing plants

The STOBER team takes a hands-on approach to help maintenance crews learn to install STOBER equipmen...

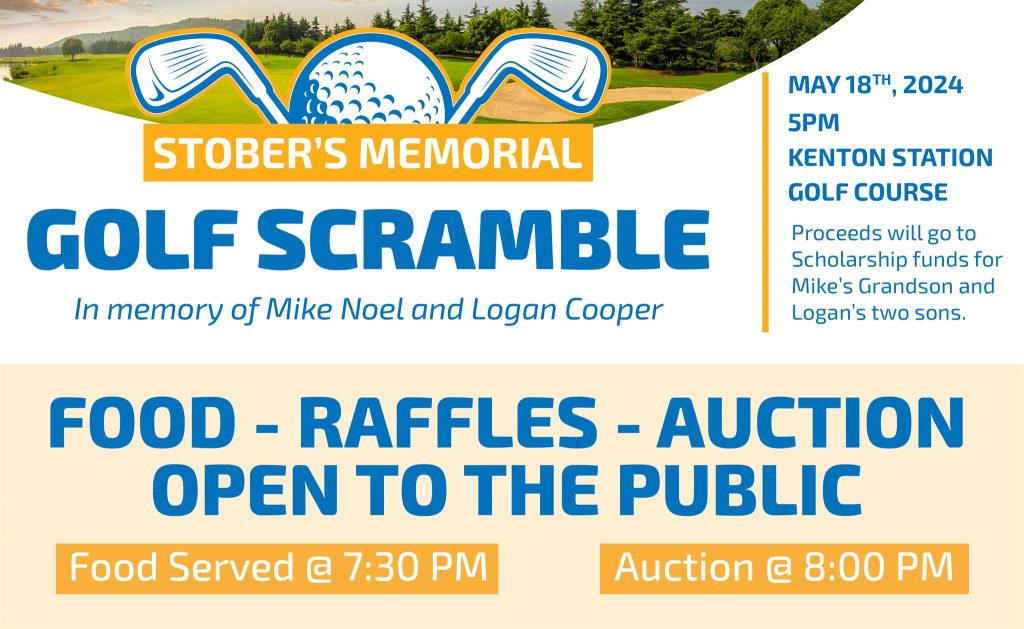

STOBER Memorial Golf Scramble to be held May 18

In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Co...

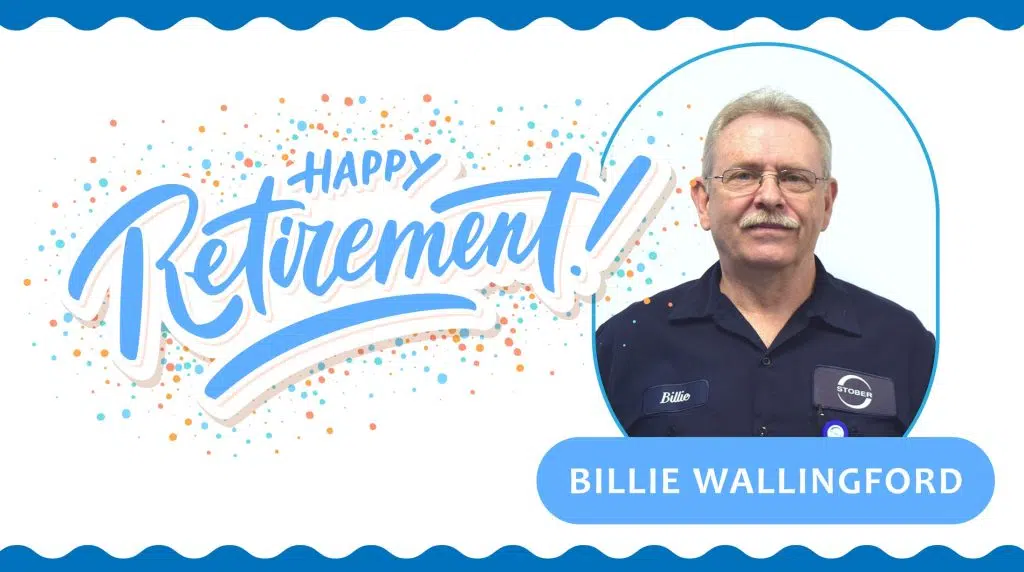

Happy Retirement, Billie Wallingford!

Billie Wallingford, a machinist on our manufacturing team, has worked at STOBER for more than 10 ye...

STOBER offers the ultimate solutions for the cheese industry

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the...

Most compact planetary geared motors just got better

The most compact planetary geared motors on the market just got better. Now with a space-saving de...

STOBER named 2024 Best Places to Work in Kentucky

STOBER Drives, Inc. is honored to be named to the 2024 list of Best Places to Work in Kentucky for m...

STOBER scholarship winners announced

STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hu...

STOBER superior in meat processing equipment

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, eq...

STOBER a proud Rockwell Automation Partner

STOBER is proud to be a member of the Rockwell Automation PartnerNetwork as part of an integrated te...

What makes a product IP69K certified?

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and...

Feil honored by MCTC

Maysville Community & Technical College (MCTC) recently honored STOBER General Manager Peter Feil fo...

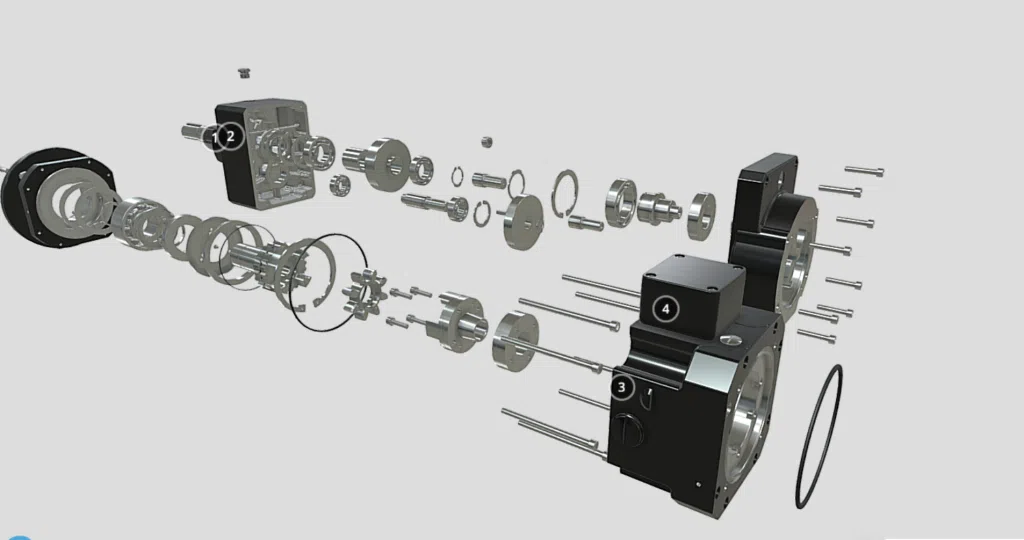

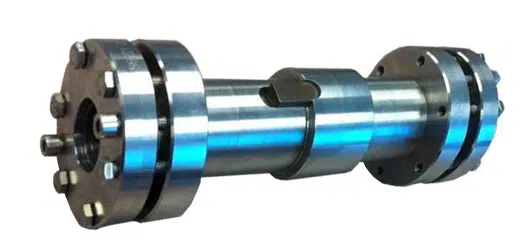

ServoStop safety brake 3D models available

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gear units, you’r...

STOBER features plug-and-play compatibility with popular drive brands

STOBER motors and geared motors are flexible in design and compatibility with third-party drives....

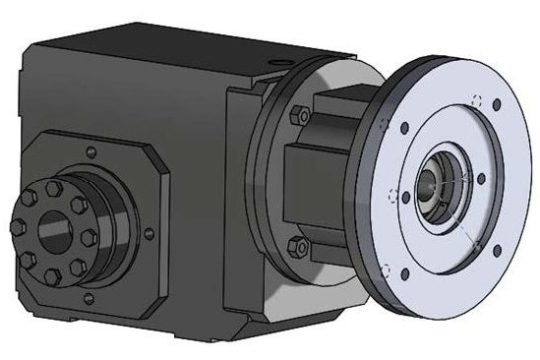

STOBER wobble-free bushing allows interchangeable mounting

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard co...

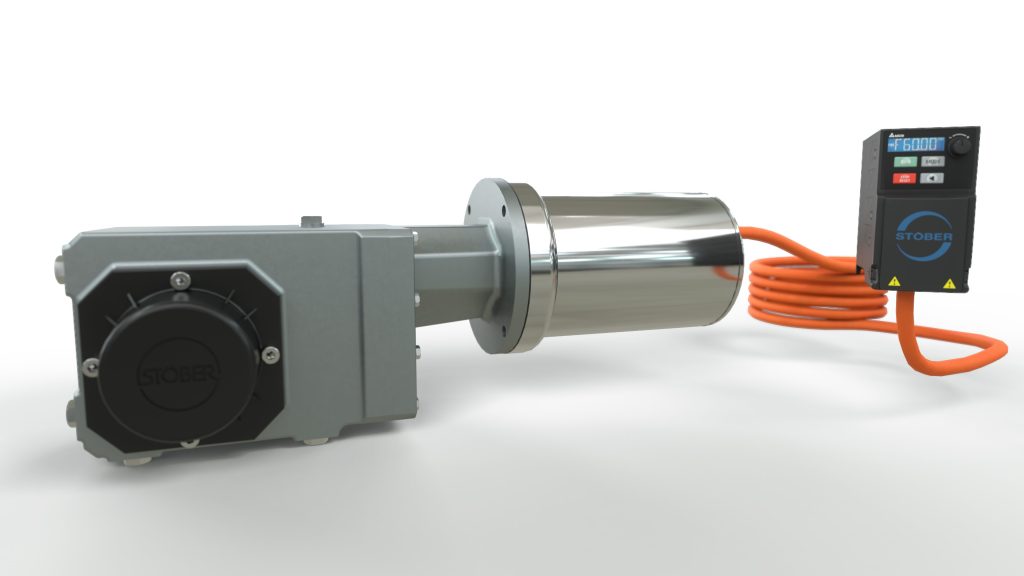

Introducing the STOBER cLEAN System

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s re...

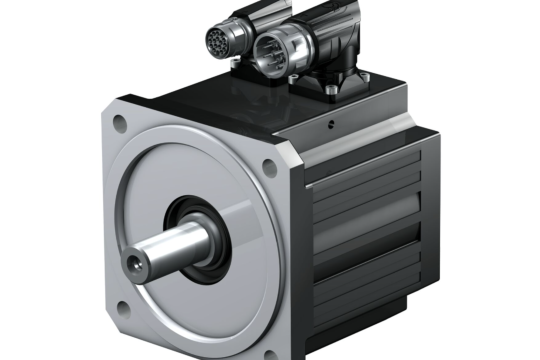

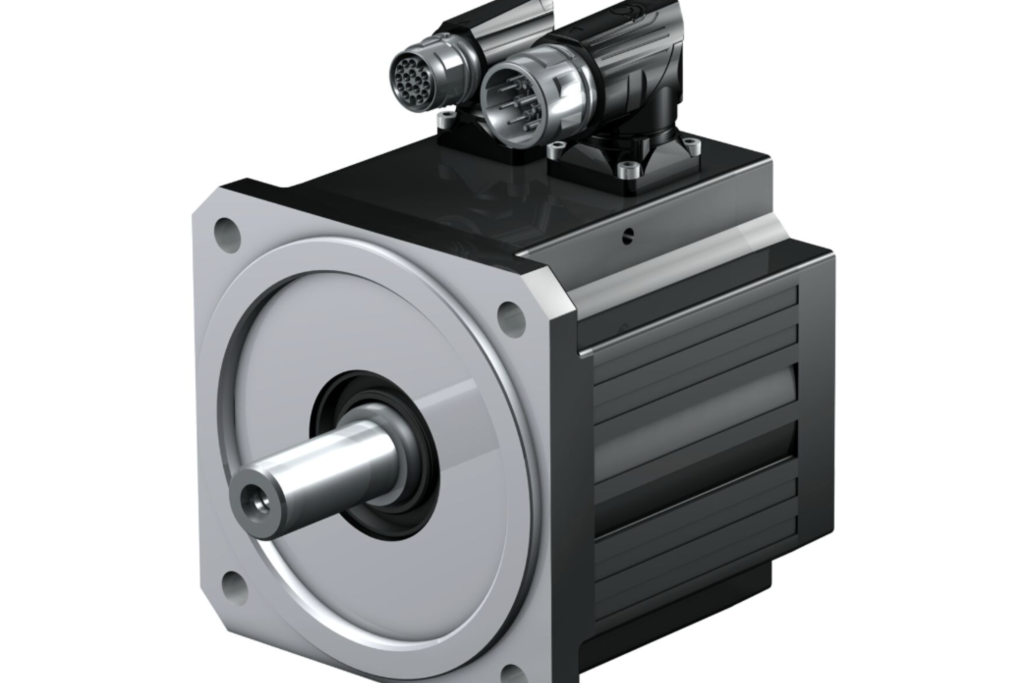

STOBER motors ready to ship from Maysville, Ky.

Are you frustrated with lead times for motors? STOBER has several options readily available from M...

Packaged synchronous servo geared motors from STOBER

Did you know STOBER’s synchronous servo geared motors are a packaged solution? Yep, you can be b...

Year in review: Top blog posts of 2023

We hope our blog has been informative, useful, and inspiring this year. As a review of 2023, we look...

STOBER featured in new Christmas movie

You’ve probably noticed the new Christmas movie, “Candy Cane Lane” on Amazon Prime. Did you ...

STOBER sales team volunteers at Maysville Hands of Hope

STOBER sales team recently volunteered to help sort donations, hang clothing, and serve lunch to sho...

OEM Renewal Program extends machine life

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdown...

STOBER solutions for food production

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdown...

STOBER drives innovation for packaging OEMs

STOBER solutions can reduce space requirements in the packaging industry and minimize components and...

STOBER’s paint process prevents flaking

STOBER’s quality paint mixture and painting process eliminates any worry about paint flaking. Ev...

Gearing up for success: Installation training at food processing plants

The STOBER team takes a hands-on approach to help maintenance crews learn to install STOBER equipment on their food production lines.

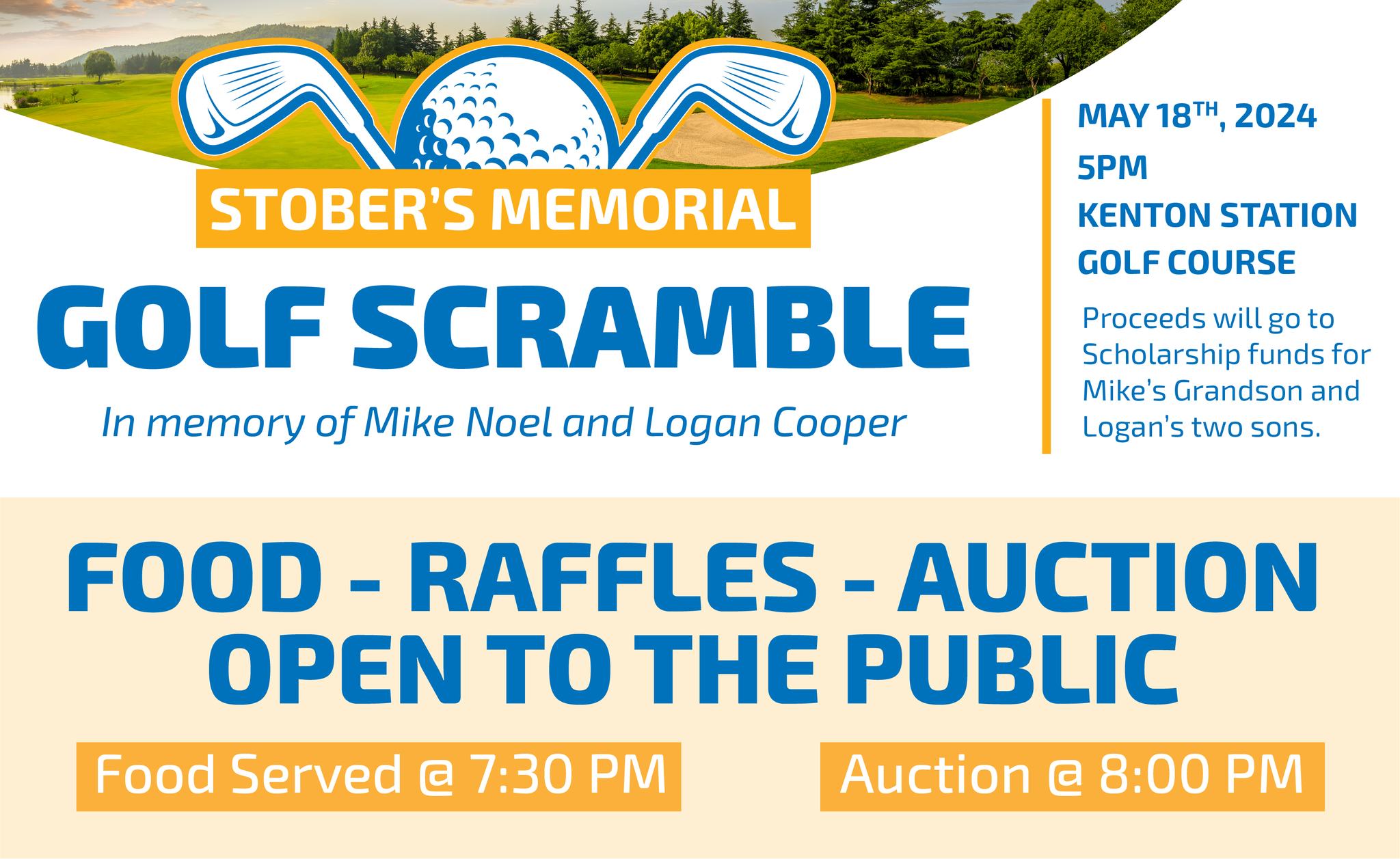

STOBER Memorial Golf Scramble to be held May 18

In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Course on Saturday, May 18. All proceeds from the event go toward a scholarship fund for Mike’s grandson and Logan’s two sons.

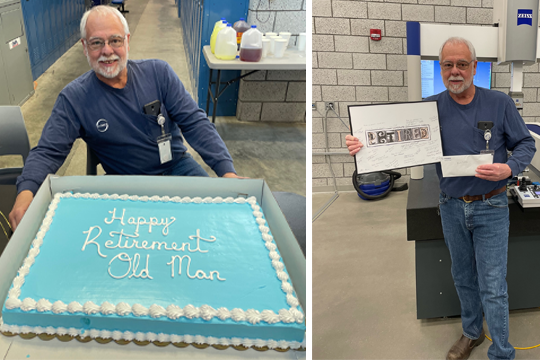

Happy Retirement, Billie Wallingford!

Billie Wallingford, a machinist on our manufacturing team, has worked at STOBER for more than 10 years and will be retiring on April 26.

STOBER offers the ultimate solutions for the cheese industry

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

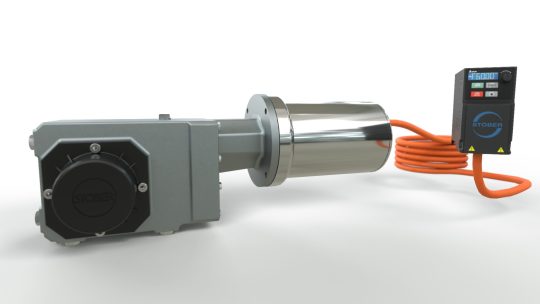

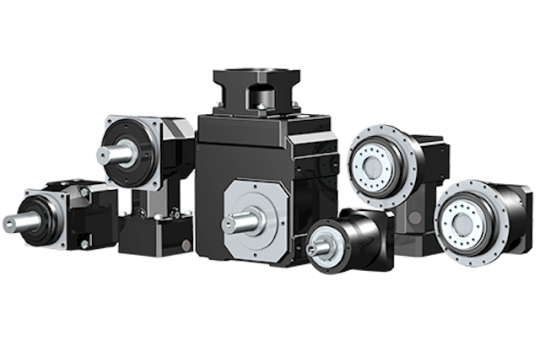

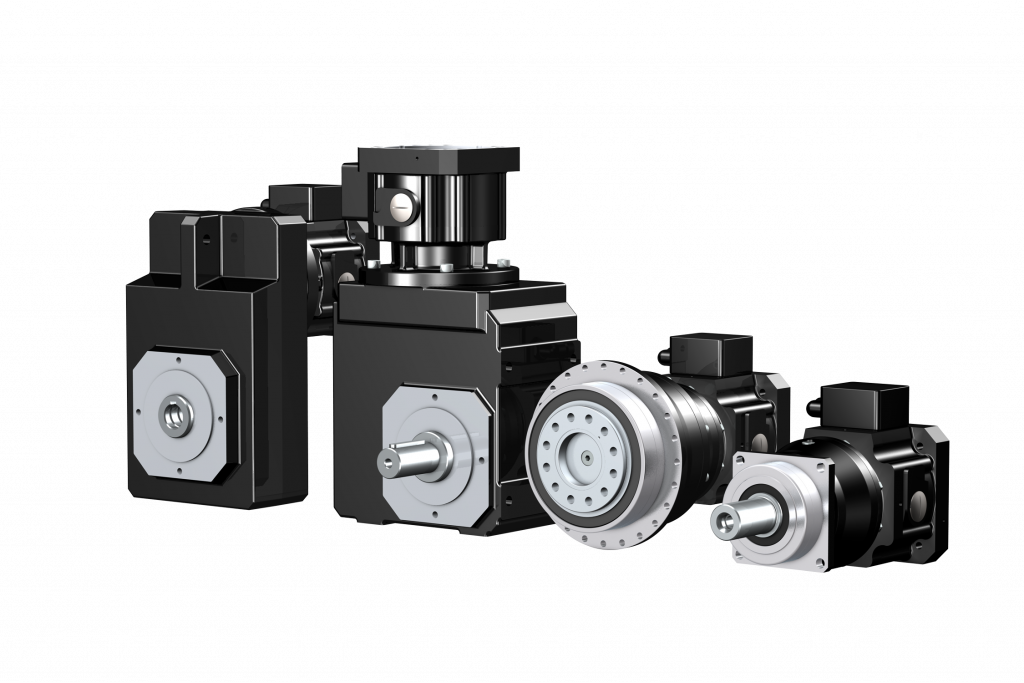

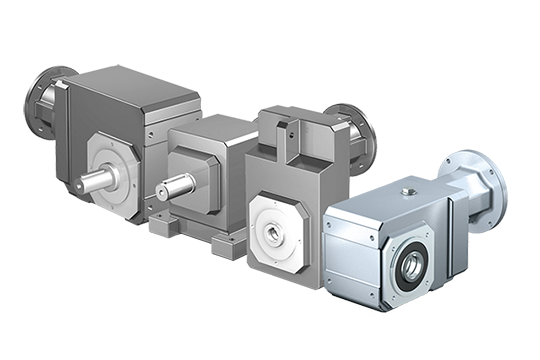

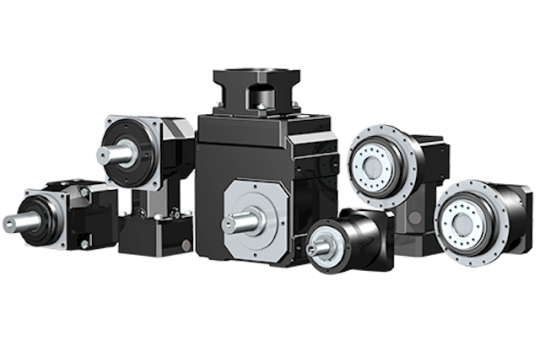

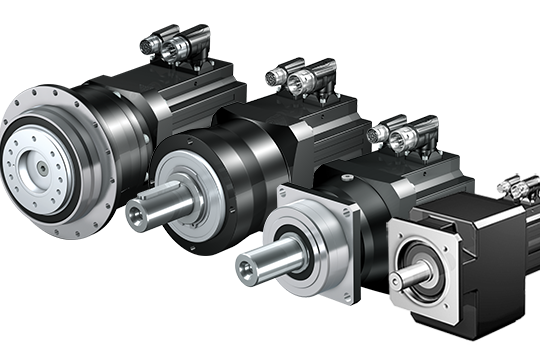

Most compact planetary geared motors just got better

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

STOBER named 2024 Best Places to Work in Kentucky

STOBER Drives, Inc. is honored to be named to the 2024 list of Best Places to Work in Kentucky for medium-sized businesses.

STOBER scholarship winners announced

STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hurst, Ray Williams and Mike Noel Memorial Scholarship.

STOBER superior in meat processing equipment

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

STOBER a proud Rockwell Automation Partner

STOBER is proud to be a member of the Rockwell Automation PartnerNetwork as part of an integrated team of engineering specialists and suppliers.

What makes a product IP69K certified?

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

Feil honored by MCTC

Maysville Community & Technical College (MCTC) recently honored STOBER General Manager Peter Feil for his service to their Board of Directors. Feil said he is very grateful for having had the opportunity to serve on the MCTC Board.

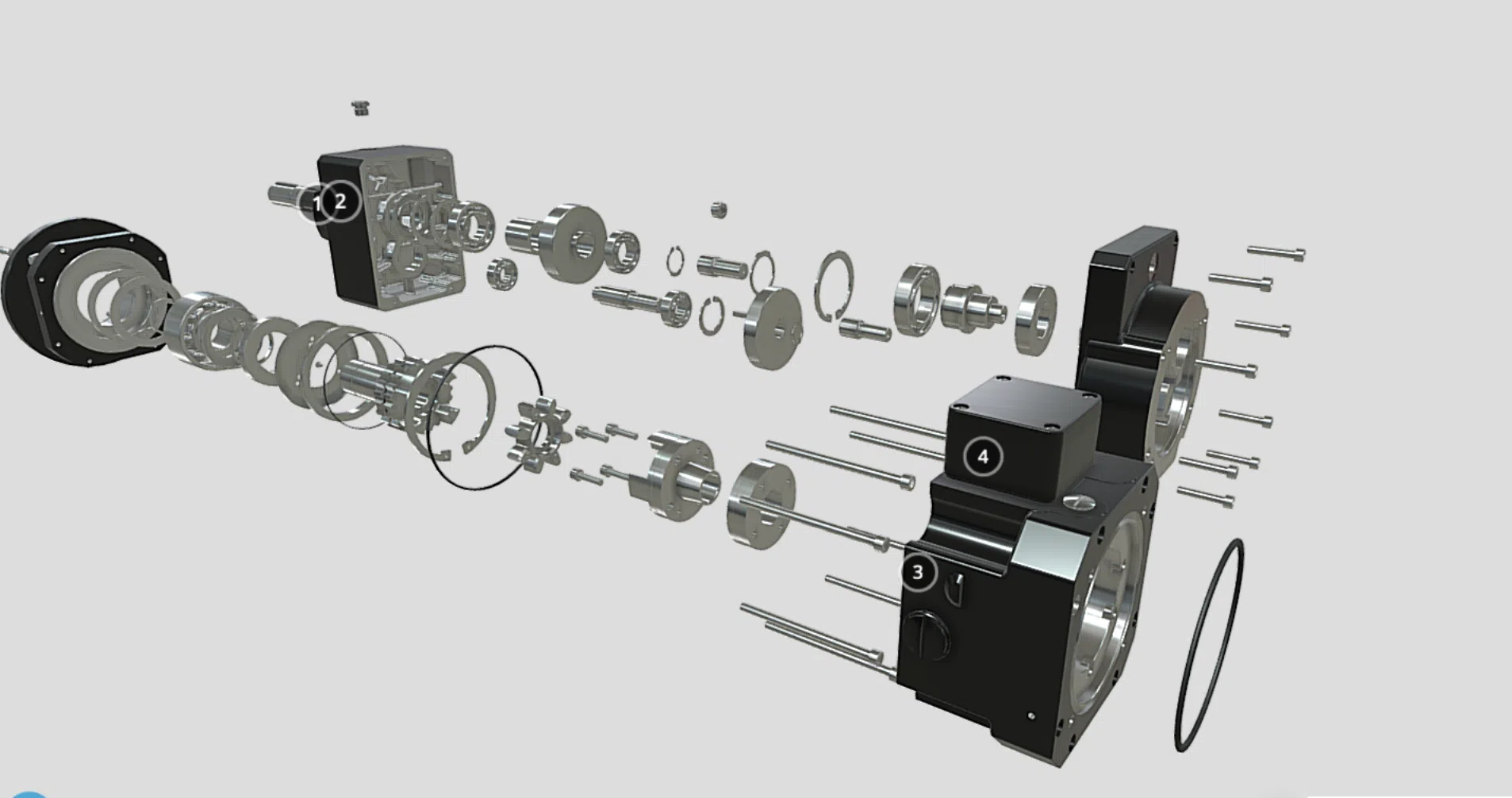

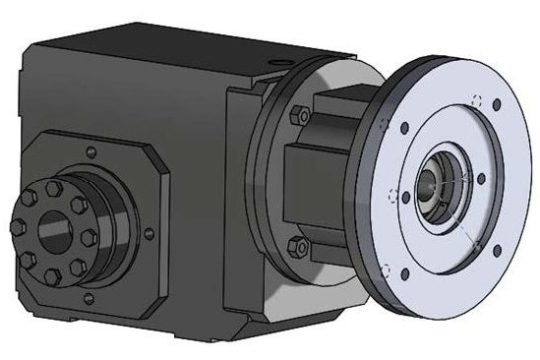

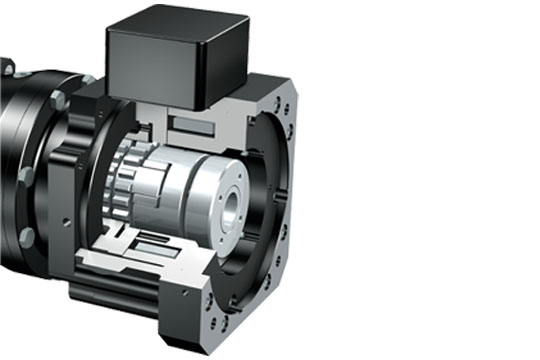

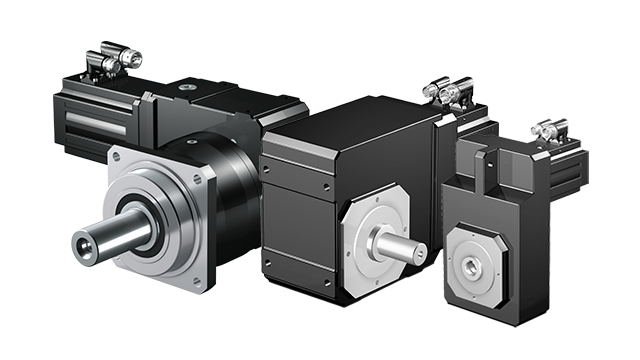

ServoStop safety brake 3D models available

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gear units, you’re in luck—3D models of the product are now available on the STOBER website!

STOBER features plug-and-play compatibility with popular drive brands

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

STOBER wobble-free bushing allows interchangeable mounting

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

Introducing the STOBER cLEAN System

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

STOBER motors ready to ship from Maysville, Ky.

Are you frustrated with lead times for motors? STOBER has several options readily available from Maysville, Ky. Our Kentucky facility stocks the EZ3 (72mm frame size), EZ4 (98mm), EZ5 (115mm), and EZ7 (145mm) motors.*

Packaged synchronous servo geared motors from STOBER

Did you know STOBER’s synchronous servo geared motors are a packaged solution? Yep, you can be back up and running faster than ever because with STOBER’s packaged solution, installation is easy.

Year in review: Top blog posts of 2023

We hope our blog has been informative, useful, and inspiring this year. As a review of 2023, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

STOBER featured in new Christmas movie

You’ve probably noticed the new Christmas movie, “Candy Cane Lane” on Amazon Prime. Did you know that it stars a STOBER gearbox!?

STOBER sales team volunteers at Maysville Hands of Hope

STOBER sales team recently volunteered to help sort donations, hang clothing, and serve lunch to shoppers who visited Maysville Hands of Hope.

OEM Renewal Program extends machine life

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

STOBER solutions for food production

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

STOBER drives innovation for packaging OEMs

STOBER solutions can reduce space requirements in the packaging industry and minimize components and maintenance—a win-win situation! Innovative designs from STOBER can reduce equipment footprint by 20 percent.

STOBER’s paint process prevents flaking

STOBER’s quality paint mixture and painting process eliminates any worry about paint flaking. Every food duty unit is washed to remove any grease that could prevent paint from properly adhering to the surface. Then, each unit is painted with four layers of paint, including an antimicrobial clear coat.

Application benefits of using a STOBER geared motor

STOBER geared motors feature options for your application’s right fit – right angle or inline, helical or planetary, encoder options, brakes, and fans.

Satisfied distributor recognizes STOBER for exceptional customer service

STOBER is proud to help keep customers up and running by supplying exceptional customer service and the gold-standard in perfect motion.

STOBER featured in Business View Magazine

STOBER Drives, Inc. is featured in the September 2023 issue of Business View Magazine.

STOBER Hydraulic Motor Adapters mean more solutions

Most hydraulic motors have 2 or 4 bolt SAE flanges. We design

adapter plates and shaft hubs to mount the motors directly to our

gearboxes, making it as easy as possible for you.

STOBER culture topic of presentation for business leaders

Peter Feil, VP/General Manager, and Stephanie Gastauer, Talent Development Leader, recently presented information about the culture of STOBER Drives, Inc. to regional business leaders who gathered at Aileron in Tripp City, Ohio.

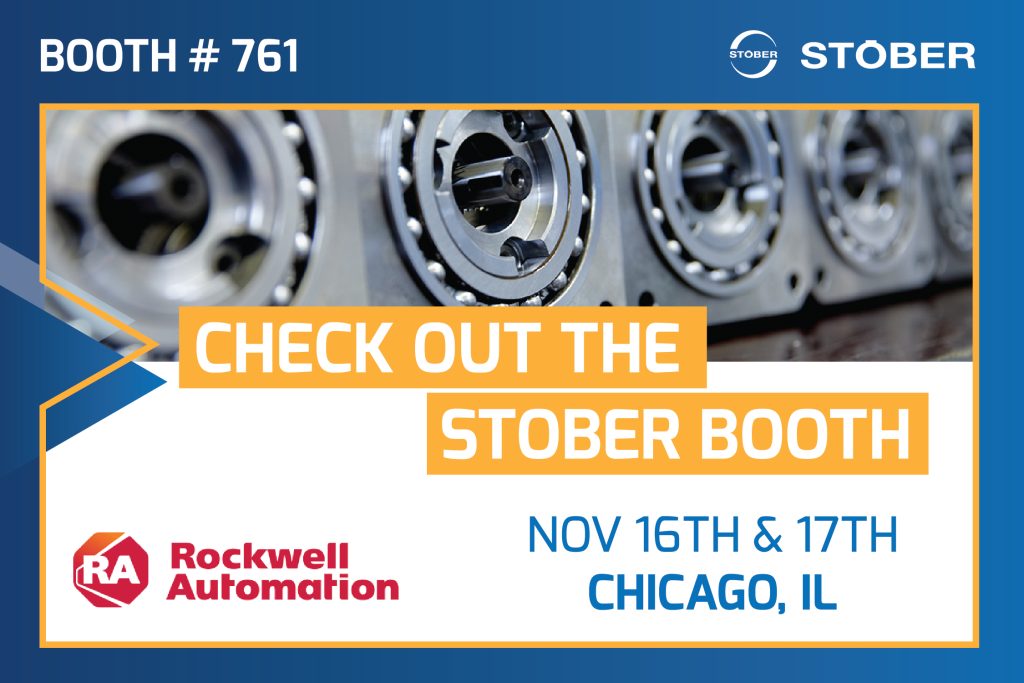

STOBER and Rockwell Automation’s partner network

STOBER partners with Rockwell Automation to deliver mechatronics solutions that enable our mutual end-customers to optimize their machine’s efficiency, create reliable solutions, and save space while being backed by an industry-leading warranty.

STOBER featured at General Mills conference

STOBER regional managers Brian Gerzsenyi, Nick Smith, and Mark Sticklen recently presented at the General Mills Maintenance & Reliability Leadership Conference. Their presentation focused on how to eliminate downtime related to gearboxes.

STOBER YouTube channel features valuable resources

If you’re unsure about how to install or perform maintenance on your STOBER gearbox and aren’t interested in reading a user’s manual to find what you need, look no further than a quick YouTube tutorial!

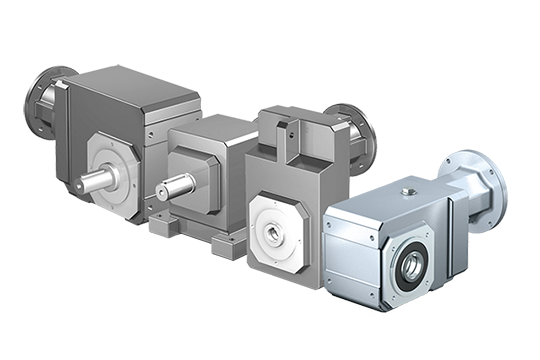

Selecting the best power transmission gearbox

With a variety of gearboxes on the market that can fulfill diverse requirements, selecting the best power transmission gearbox can be a challenge. Avoid making a wrong decision to avoid wasting money on a more expensive gearbox that isn’t necessary.

STOBER 3D modeling brings new perspective

As a consumer, you use 3D modeling when you research items such as cars, clothing, shoes, and appliances online, so why shouldn’t you see 3D models of your gearboxes too? Now you can with STOBER’s new 3D modeling tools.

Virtual customer meetings help STOBER increase efficiency

If you have questions about our products you’d like answered, a tough application you need a solution for, or just want to touch base and put a name with a face, us our Meeting Request tool to schedule some one-on-one time with our team!

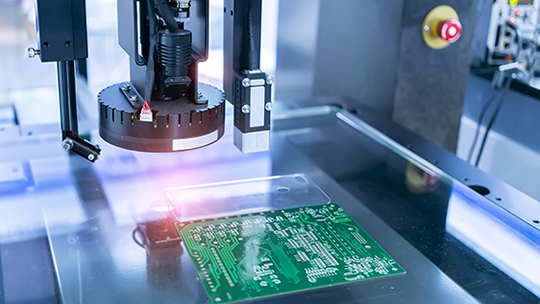

STOBER can improve machine reliability

Learn how STOBER can help improve your machine reliability and combat other common struggles for the semiconductor industry.

STOBER Oktoberfest Stein Dash Aug. 12

Join us at Maysville Oktoberfest on Saturday, Aug. 12 from 4 p.m. to 6 p.m. and find out at the STOBER Stein Dash!

STOBER can build & ship in one day from Maysville, Ky.

At STOBER, we’re proud to build and ship in only one day from our facility in Maysville, Kentucky, so our customers don’t have to worry about lead times.

Happy Retirement, Doug Reeves!

Doug Reeves, service team leader, has enjoyed working at STOBER for the past four years and is retiring July 21.

STOBER lunch benefit a success

Our HR team prepared sack lunches last week and raised more than $800 to benefit Christy Wilson Kirk, daughter of Bill & Cheryl. Cheryl’s Cleaning Service takes care of our custodial needs.

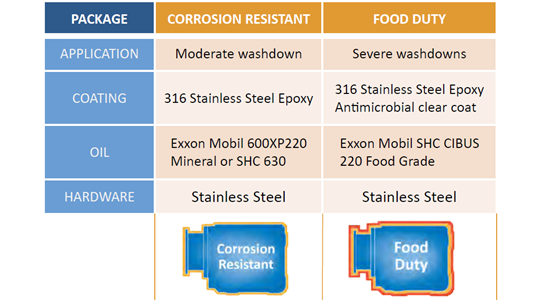

Geared motors for washdown applications

STOBER’s synchronous Servo geared motors are available in food duty or corrosion resistant options to meet washdown requirements.

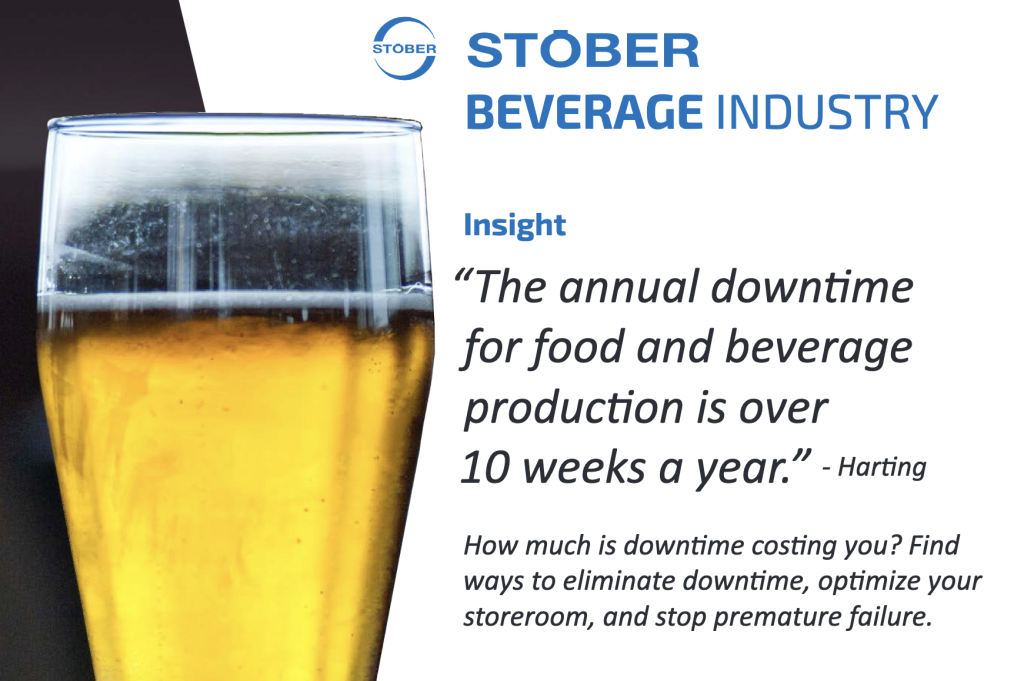

STOBER solutions for the beverage industry

STOBER’s NEMA right-angle gearboxes are ideal to keeping downtime minimized in the beverage industry.

STOBER servo geared motors have many advantages

STOBER servo geared motors consist of a gearbox assembled onto the motor for a lighter, more compact solution with less maintenance.

STOBER named 2023 Best Places to Work in Kentucky

STOBER Drives, Inc. was named eighth on the list of Best Places to Work in Kentucky for medium-sized businesses.

Power transmission principles strengthen STOBER product specialists

STOBER engineers recently completed training for motors and controls through hands-on learning experiences at the historic Cox Building in downtown Maysville.

STOBER hydraulic motor adapters

When it comes to using a hydraulic motor adapter with a STOBER gearbox, it has never been easier!

Cable best practices

Best practices when installing and connecting cables in a manufacturing environment ensures safety and extends equipment life.

Learn more: Industrial Ethernet Communication Protocols

Higher speeds and greater throughputs are features of new industrial ethernet communications protocols, which can be paired with STOBER motors and geared motors.

STOBER product specialists better equipped to serve customers

STOBER engineers recently completed training for motors and controls through hands-on learning experiences at the historic Cox Building in downtown Maysville.

STOBER engineers complete motors and controls training

STOBER engineers recently completed training for motors and controls through hands-on learning experiences at the historic Cox Building in downtown Maysville.

STOBER provides optimal machine design & maximum performance

STOBER is proud to be the gold standard, with top-notch industry knowledge and industry-leading products to provide the ultimate solution in any environment.

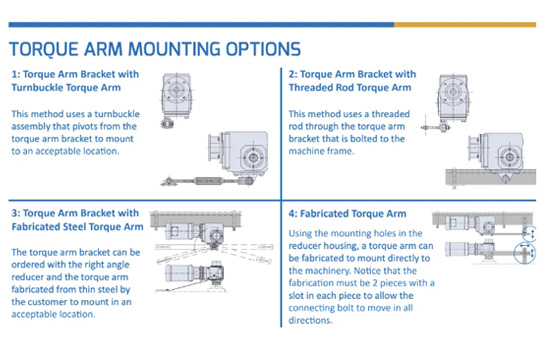

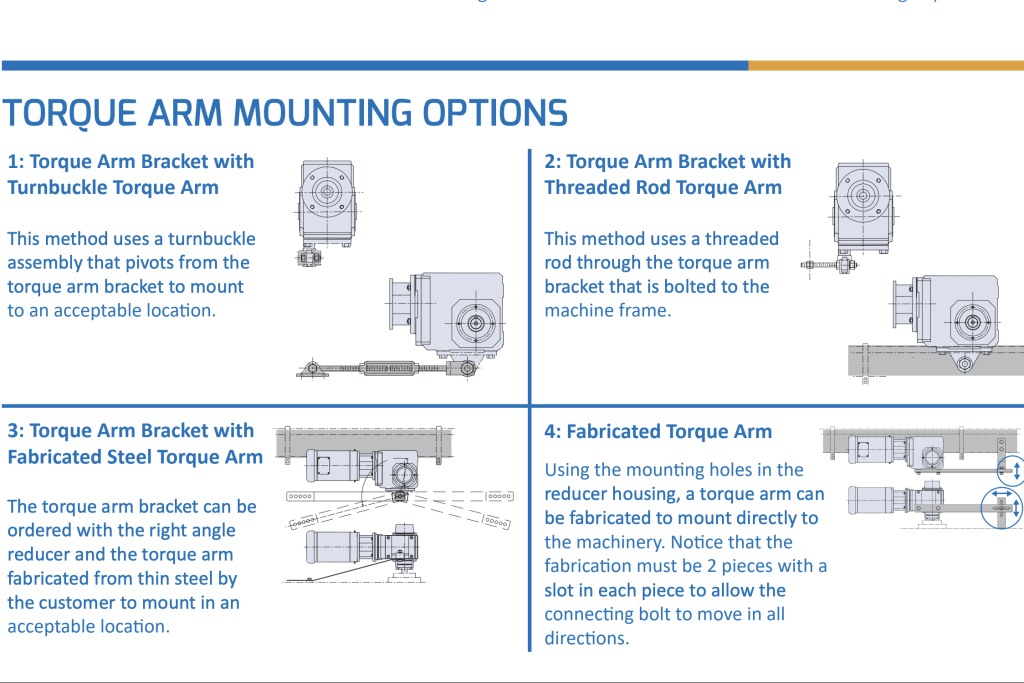

STOBER eliminates gearing misalignment

STOBER eliminates gearing misalignment, preventing premature failure through free installation training and a variety of torque arm mounting options.

2022 STOBER Rep Awards announced

STOBER sales reps have the expertise and industry knowledge to provide customers with the best solutions for their applications. 2022 Rep Awards are announced.

Happy Retirement, Rick Fields!

Rick Fields, quality tech, has enjoyed everything about working at STOBER for the past 8 1/2 years and is retiring at the end of March.

Vote for STOBER, Coolest Thing Made in Kentucky

STOBER’s synchronous servo geared motors have been nominated for the 2023 Coolest Thing Made in Kentucky Tournament. Cast your vote today!

STOBER ServoStop designed for redundant braking

When an assembly line needs to stop immediately due to a hazardous situation, you need STOBER ServoSoft designed for redundant braking power.

STOBER’s servo gear units outperform the competition

STOBER’s servo gear units outperform the competition when it comes to performance, backlash, running temperature, and compatibility.

STOBER hosting high school open house April 12

STOBER will host an open house for interested high school juniors and seniors on April 12, 2023.

Is STOBER’s ServoStop safety brake ideal for your application?

Did you know STOBER’s servo gear units can be paired with ServoStop, a revolutionary integrated safety brake? It’s ideal for vertical applications, provides redundant braking, and prevents slipping or falls even when the motor is removed.

STOBER: The least expensive gearbox you’ll ever own

STOBER gearboxes are the least expensive you’ll ever own. From no maintenance to storeroom optimization to energy efficiency and more, let us show you how we can save you money.

Selecting the best gearbox oil

Gearbox oil leaks can be a maintenance nightmare – especially in food or beverage applications. STOBER knows differences matter, which is why we evaluate our lubrication thoroughly.

STOBER tools and software for the life of your application

STOBER offers several free tools and software to help implement the best mechatronic solution for your application.

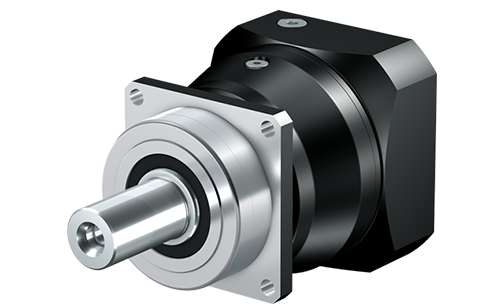

STOBER features bearing options for planetary

STOBER’s planetary series allows you to choose from several bearing options to handle radial or axial loads, optimizing your machine design.

EZ3 motors now assembled in Maysville, Ky.

STOBER Drives, Inc. is proud to announce that EZ3 motors are now being assembled at our Maysville, Ky. facility with a standard one-week lead time.

Using the STOBER Configurator—easy as 1, 2, 3!

Whether it’s a gear unit, motor, or rack and pinion, put down the catalogs and find what you need with a few simple clicks!

Year in Review: Top blog posts of 2022

As a review of 2022, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

Twas the night before STOBER Christmas

Twas the night before Christmas and all through the plant, not a creature was stirring not even an ant…

STOBER saves time during machine design

Design engineers deal with numerous obstacles when creating a machine – inefficient supplier communication, limited design time, and unfamiliarity with a brand all add up. These delays can make the engineer miss an important deadline. But don’t worry–STOBER can help overcome these challenges.

Aftermarket support from STOBER

STOBER’s service department offers several levels of expert analysis to inspect products after they have been installed in the field. With a standard five-day turnaround for the basic evaluation, our team is committed to having you back up and running as quickly as possible.

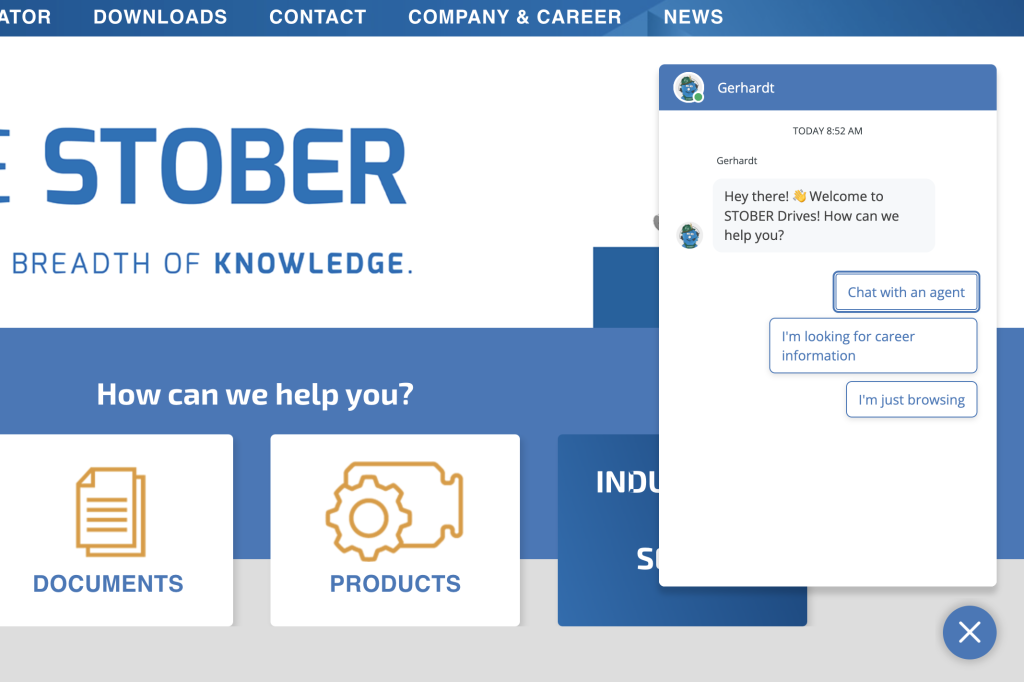

Introducing the Gerhardt Guide

Drumroll, please! Now introducing The Gerhardt Guide, a comic about adventures in the life of Gerhardt Gearhead!

STOBER right-angle geared motors to optimize machine design

Planetary or helical, STOBER has the range of products you need to optimize your machine design. STOBER servo right-angle geared motors are available as either planetary right-angle geared motors or helical-bevel geared motors.

Meet Gerhardt Gearhead, STOBER’s jolly mascot

We’re sure you’ve seen a jolly blue mascot popping up on our social media lately and have begun wondering where he bought those nice lederhosen! The wait is over–Gerhardt Gearhead is ready to share his story.

STOBER to be featured at Automation Fair forum Nov. 16-17

STOBER Drives, Inc. will be in attendance at Rockwell Automation’s Automation Fair in Chicago on Nov. 16-17, 2022. Representatives will be available in booth 761 to share information about STOBER’s premium gearing solutions.

STOBER synchronous servo motors up for any challenge

STOBER’s synchronous servo motors are compact, dynamic, and powerful. Direct mounting results in higher torque density and stiffness while reducing inertia by up to 75 percent.

How proper alignment can stop gear reducer failure

Did you know that premature gearbox failure can be caused by gearing misalignment? Keep reading to find out how premature failure can be eliminated by ensuring proper alignment.

Top 5 advantages of STOBER over motorized pulleys

Heat is the natural enemy of a gearbox, so why not do everything you can to keep the temperature down? STOBER performs at a 12 percent reduction in temperature versus the competition.

STOBER: The environmentally friendly gearbox

High-speed machines often increase the ambient temperature, which can be bad news for a gearbox. Since heat is the natural enemy of a gearbox, STOBER offers many ways to keep the temperature down.

Need to eliminate heat? STOBER runs 12 percent cooler than the competition

Heat is the natural enemy of a gearbox, so why not do everything you can to keep the temperature down? STOBER performs at a 12 percent reduction in temperature versus the competition.

Upgrade your OEM equipment with STOBER

Asset reliability means you can depend on a STOBER gear reducer for years, which increases profits and surpasses plant efficiency targets.

New STOBER stabilizer bracket simplifies installation

If you’re tired of repeatedly replacing the same failing gearbox, STOBER has a new solution for you!

Apprenticeships post-COVID – more relevant than ever

With ever-increasing shortages in skilled workers throughout America, it’s more important than ever for businesses to invest in the development of their employees. What better way to fill the talent shortage gap than to implement an apprenticeship program? Read more about how STOBER finds success in offering apprenticeships.

STOBER adds new tools for virtual customer meetings

Many people have come to prefer meeting via Zoom, GoogleMeet, or Microsoft Teams to discuss potential projects, recap progress, or follow up on future plans. STOBER decided to offer an easy, convenient way for customers to set up virtual meetings to make communication easier and more effective in the digital world.

Top three considerations for global machine support

When your company supplies machines all around the globe, it’s important to find a supplier of mechatronic products that works in a variety of markets and fulfills a variety of applications. From the simplest to the harshest application, getting worldwide support can be difficult. Be sure to consider these three things when seeking…

STOBER Drives approved for incentive funding

The Kentucky Economic Development Finance Authority (KEDFA) preliminarily approved a 15-year incentive agreement with STOBER under the Kentucky Business Investment program.

Top five things to consider when selecting gearbox oil

When making a gearbox purchase decision, oil is a seemingly small detail but can make a huge difference in your gearbox’s life.

STOBER servo gear units optimize operational performance

STOBER gearheads survive in the toughest environments, providing long life under extreme conditions. Their high reliability and durability saves non-productive downtime and cost.

STOBER: The environmentally friendly gearbox

Many plants have $1 million of products in the storeroom, plus the cost of time and space to stock, maintain, and manage it. STOBER can help reduce the need for expensive storerooms.

How to Prevent Gearbox Water Ingress

Prevent premature gearbox failure with one simple trick—eliminating water or chemical ingress in your gearbox! Read more to learn how.

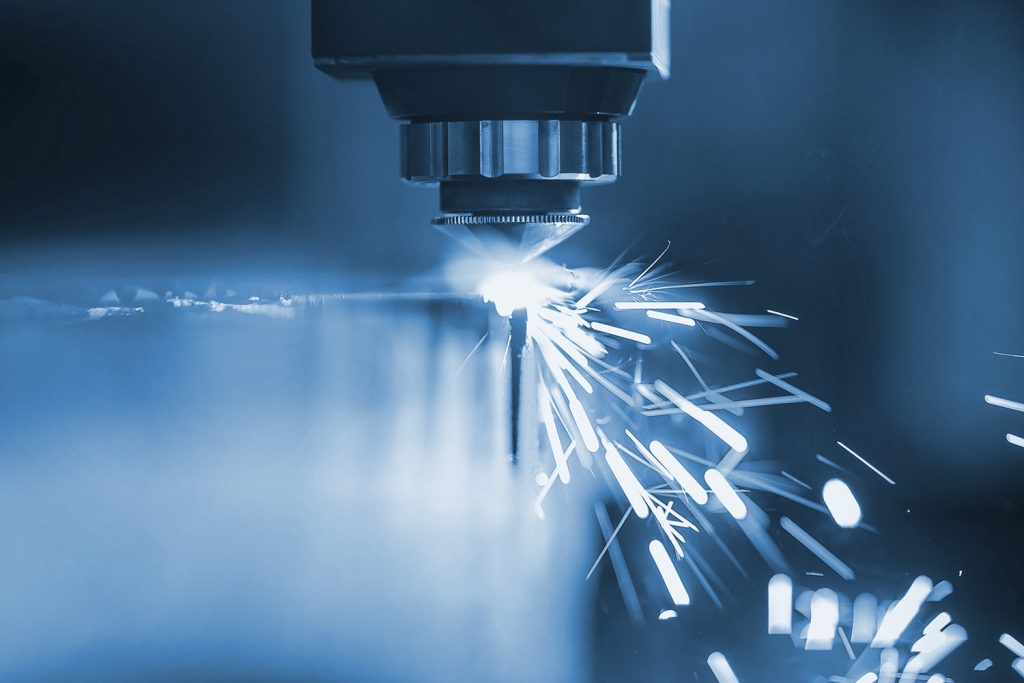

STOBER’s Machine Tool Design features accuracy, stiffness, and longevity

Accuracy, stiffness, and life are all important in machine tool design. STOBER has the knowledge and products to successfully accomplish all three.

Top 5 advantages of STOBER’s servo geared motors

Geared motors can improve machine design while saving money. By eliminating extra components, such as the motor coupling, the solution is lighter and more compact. Plus, wear components are reduced, which equals less maintenance. There are many other benefits to a geared motor—read more about the top five below.

STOBER live chat makes it easy to get the info you need

Chat with an engineer for help with part numbers, troubleshooting, identifying solutions for your application, and more.

What are Industrial Ethernet Communication Protocols?

STOBER motors and geared motors are used in many different applications where the customer has implemented the communication protocol of their choice upstream in their application. Contact us today to see how we can help you find the optimal solution for your application.

STOBER inducted into “Best Places to Work in Kentucky” Hall of Fame

est Places to Work in Kentucky for the fifth straight year, earning a spot in the Hall of Fame.

How STOBER values Responsibility

STOBER values responsibility. But what does that mean? Check out our blog to read about one employee’s explanation.

How does Hiperface DSL work?

STOBER geared motors and motors are Hiperface DSL compatible, but how does it work and what are the advantages? Read more.

How STOBER values Innovation: It’s what drives us

Continual improvement in the workplace, products, and solutions gives STOBER an advantage over the competition.

STOBER employee completes Boston Marathon

STOBER is not only proud to feature the world’s toughest gearbox, but also some of the world’s toughest people!

How do you differentiate EnDat versions?

There are several versions of EnDat. What are the differences in each one?

Save money with optimal gearbox selection

Don’t waste money on an expensive, under-performing gearbox. Get tips from STOBER for selecting the best gearbox for your application.

How STOBER Values Teamwork

Building a strong team environment is a critical part of STOBER’s culture.